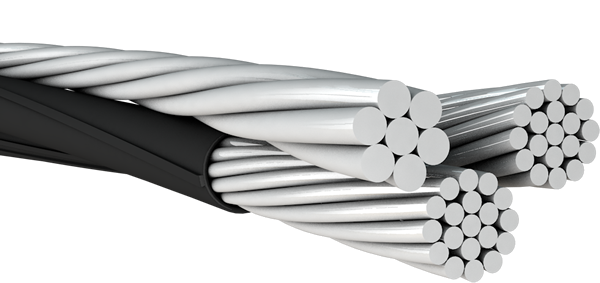

SERVICE DROP

CABLE - TRIPLEX

APPLICATION:

To supply power from the utility’s lines to the consumer’s weatherhead. For service at 600 volts or less (phase to phase) at a conductor temperature of 75°C maximum for polyethylene insulation or 90°C maximum for crosslinked polyethylene (XLP) insulated conductors.

PRODUCT FEATURES:

Conductors are concentrically stranded, compressed 1350-H19 aluminum. Insulated with either polyethylene or XLP crosslinked polyethylene. Neutral messengers are concentrically stranded 6201, AAC or ACSR.

STANDARDS:

Service drop cable meets or exceeds the following ASTM specifications:

• B-230 Aluminum Wire, 1350-H19 for Electrical Purposes

• B-231 Aluminum Conductors, Concentric-Lay-Stranded

• B-232 Aluminum Conductors, Concentric-Lay-Stranded,

Coated Steel Reinforced (ACSR)

• B-399 Concentric-Lay-Stranded, 6201-T81 Aluminum Alloy Conductors

• B-901 Compressed Round Stranded Aluminum Conductors

Using Single Input Wire

• ANSI/ICEA S-76-474

|

KINGWIRE Triplex Service Drop - AAAC-Alloy Neutral Messenger |

||||||||||

|

Code Word |

Phase Conductors |

Bare Neutral |

Weight |

Rating |

||||||

|

Size |

Strand |

Insulation Thickness |

Size |

Strand |

Breaking |

XLP |

Poly |

XLP |

Poly |

|

|

Minex |

6 |

Solid |

45 |

6 |

7 |

1,110 |

106.6 |

102.9 |

85 |

70 |

|

Hippa |

6 |

7/w |

45 |

6 |

7 |

1,110 |

107.0 |

105.7 |

85 |

70 |

|

Prawn |

4 |

Solid |

45 |

4 |

7 |

1,760 |

158.4 |

154.1 |

110 |

90 |

|

Barnacles |

4 |

7/w |

45 |

4 |

7 |

1,760 |

160.0 |

157.0 |

110 |

90 |

|

Shrimp |

2 |

7/w |

45 |

2 |

7 |

2,800 |

243.0 |

238.0 |

150 |

115 |

|

Gammarus |

1/0 |

7/w |

60 |

1/0 |

7 |

4,460 |

390.0 |

384.0 |

200 |

155 |

|

Leda |

1/0 |

19/w |

60 |

1/0 |

7 |

4,460 |

384.0 |

378.0 |

200 |

155 |

|

Dungenese |

2/0 |

7/w |

60 |

2/0 |

7 |

5,390 |

481.0 |

474.0 |

230 |

180 |

|

Cyclops |

2/0 |

19/w |

60 |

2/0 |

7 |

5,390 |

473.0 |

467.0 |

230 |

180 |

|

Flustra |

3/0 |

19/w |

60 |

3/0 |

7 |

6,790 |

596.0 |

589.1 |

260 |

205 |

|

Lepas |

4/0 |

19/w |

60 |

4/0 |

7 |

8,560 |

725.0 |

716.0 |

300 |

235 |

|

KINGWIRE Triplex Service Drop - Aluminum Conductor - AAAC - Alloy Reduced Neutral Messenger |

||||||||||

|

Code Word |

Phase Conductors |

Bare Neutral |

Weight |

Rating |

||||||

|

Size |

Strand |

Insulation Thickness |

Size |

Strand |

Breaking |

XLP |

Poly |

XLP |

Poly |

|

|

Artemia |

4 |

Solid |

45 |

6 |

7 |

1,110 |

134.0 |

132.0 |

110 |

90 |

|

Crab |

4 |

7/w |

45 |

6 |

7 |

1,110 |

144.0 |

141.2 |

110 |

90 |

|

Solaster |

2 |

7/w |

45 |

4 |

7 |

1,760 |

216.0 |

212.6 |

150 |

115 |

|

Sandcrab |

1/0 |

7/w |

60 |

2 |

7 |

2,800 |

348.0 |

341.0 |

200 |

155 |

|

Echinus |

1/0 |

19/w |

60 |

2 |

7 |

2,800 |

342.0 |

336.0 |

200 |

155 |

|

Crayfish |

2/0 |

7/w |

60 |

1 |

7 |

3,530 |

452.6 |

422.5 |

230 |

180 |

|

Sipho |

2/0 |

19/w |

60 |

1 |

7 |

3,530 |

441.0 |

422.5 |

230 |

180 |

|

Fulgar |

3/0 |

19/w |

60 |

1/0 |

7 |

4,460 |

525.0 |

518.0 |

260 |

205 |

|

Arca |

4/0 |

19/w |

60 |

2/0 |

7 |

5,360 |

640.0 |

632.0 |

300 |

235 |

|

KINGWIRE Triplex Service Drop - Aluminum Conductor - AAC - Neutral Messenger |

||||||||||

|

Code Word |

Phase Conductors |

Bare Neutral |

Weight |

Rating |

||||||

|

Size |

Strand |

Insulation Thickness |

Size |

Strand |

Breaking |

XLP |

Poly |

XLP |

Poly |

|

|

Haiotis |

6 |

Solid |

45 |

6 |

7 |

563 |

102.5 |

98.8 |

85 |

70 |

|

Patella |

6 |

7/w |

45 |

6 |

7 |

563 |

104.0 |

101.6 |

85 |

70 |

|

Fusus |

4 |

Solid |

45 |

4 |

7 |

881 |

151.9 |

147.6 |

110 |

90 |

|

Oyster |

4 |

7/w |

45 |

4 |

7 |

881 |

154.0 |

151.7 |

110 |

90 |

|

Clam |

2 |

7/w |

45 |

2 |

7 |

1,350 |

232.0 |

228.0 |

150 |

115 |

|

Murex |

1/0 |

7/w |

1/0 |

1/0 |

7 |

1,990 |

374.0 |

367.0 |

200 |

155 |

|

Purpura |

1/0 |

19/w |

1/0 |

1/0 |

7 |

1,990 |

368.0 |

362.0 |

200 |

155 |

|

Nassa |

2/0 |

7/w |

2/0 |

2/0 |

7 |

2,510 |

461.0 |

453.0 |

230 |

180 |

|

Melita |

3/0 |

19/w |

3/0 |

3/0 |

19 |

3,310 |

585.2 |

562.9 |

260 |

205 |

|

Portunus |

4/0 |

19/w |

4/0 |

4/0 |

19 |

4,020 |

693.0 |

684.0 |

300 |

235 |

|

Nannynose |

336.4 |

19/w |

336.4 |

336.4 |

19 |

6,146 |

1,111.0 |

1,096.0 |

380 |

290 |

|

KINGWIRE Triplex Service Drop - Aluminum Conductor - Full Size ACSR Messenger |

||||||||||

|

Code Word |

Phase Conductors |

Bare Neutral |

Weight |

Rating |

||||||

|

Size |

Strand |

Insulation Thickness |

Size |

Strand |

Breaking |

XLP |

Poly |

XLP |

Poly |

|

|

Paludina |

6 |

Solid |

45 |

6 |

6/1 |

1,190 |

114 |

113 |

85 |

70 |

|

Voluta |

6 |

7/w |

45 |

6 |

6/1 |

1,190 |

115 |

112 |

85 |

70 |

|

Whelk |

4 |

Solid |

45 |

4 |

6/1 |

1,860 |

163 |

161 |

110 |

90 |

|

Periwinkle |

4 |

7/w |

45 |

4 |

6/1 |

1,860 |

172 |

169 |

110 |

90 |

|

Conch |

2 |

7/w |

45 |

2 |

6/1 |

2,850 |

262 |

257 |

150 |

115 |

|

Neritina |

1/0 |

7/w |

60 |

1/0 |

6/1 |

4,380 |

420 |

414 |

200 |

115 |

|

Cenia |

1/0 |

19/w |

60 |

1/0 |

6/1 |

4,380 |

414 |

408 |

200 |

115 |

|

Runcina |

2/0 |

7/w |

60 |

2/0 |

6/1 |

5,310 |

519 |

512 |

230 |

180 |

|

Triton |

2/0 |

19/w |

60 |

2/0 |

6/1 |

5,310 |

511 |

505 |

230 |

180 |

|

Cherrystone |

3/0 |

7/w |

60 |

3/0 |

6/1 |

6,620 |

656 |

643 |

260 |

205 |

|

Mursia |

3/0 |

19/w |

60 |

3/0 |

6/1 |

6,620 |

633 |

626 |

260 |

205 |

|

Razor |

4/0 |

7/w |

60 |

4/0 |

6/1 |

8,350 |

814 |

799 |

300 |

235 |

|

Zuzara |

4/0 |

19/w |

60 |

4/0 |

6/1 |

8,350 |

785 |

777 |

300 |

235 |

|

Limpet |

336.4 |

19/w |

80 |

336.4 |

18/1 |

8,680 |

1,160 |

1,147 |

300 |

290 |

|

KINGWIRE Triplex Service Drop - Aluminum Conductor - ACSR Reduced Size Messenger |

||||||||||

|

Code Word |

Phase Conductors |

Bare Neutral |

Weight |

Rating |

||||||

|

Size |

Strand |

Insulation Thickness |

Size |

Strand |

Breaking |

XLP |

Poly |

XLP |

Poly |

|

|

Scallop |

4 |

Solid |

45 |

6 |

6/1 |

1,190 |

142 |

139 |

110 |

90 |

|

Strombus |

4 |

7/w |

45 |

6 |

6/1 |

1,190 |

151 |

148 |

110 |

90 |

|

Cockle |

2 |

7/w |

45 |

4 |

6/1 |

1,860 |

228 |

224 |

150 |

115 |

|

Janthina |

1/0 |

7/w |

60 |

2 |

6/1 |

2,850 |

367 |

360 |

200 |

155 |

|

Ranella |

1/0 |

19/w |

60 |

2 |

6/1 |

2,850 |

361 |

356 |

200 |

155 |

|

Cavolinia |

2/0 |

7/w |

60 |

1 |

6/1 |

3,550 |

452 |

444 |

230 |

180 |

|

Clio |

2/0 |

19/w |

60 |

1 |

6/1 |

3,550 |

444 |

437 |

230 |

180 |

|

Sanddollar |

3/0 |

7/w |

60 |

1/0 |

6/1 |

4,380 |

570 |

557 |

260 |

205 |

|

Aega |

3/0 |

19/w |

60 |

1/0 |

6/1 |

4,380 |

565 |

552 |

260 |

205 |

|

Cutlefish |

4/0 |

7/w |

60 |

2/0 |

6/1 |

5,310 |

706 |

691 |

300 |

235 |

|

Cerapus |

4/0 |

19/w |

60 |

2/0 |

6/1 |

5,310 |

678 |

670 |

300 |

235 |

|

Cowry |

336.4 |

19/w |

80 |

4/0 |

6/1 |

8,350 |

1,135 |

1,093 |

380 |

290 |

* Note: Designated sizes are ACSR 6/1 diameter equivalent resistivity per ASTM-B-399 for 6201. Conductor temperature of 90°C for XLP, 75°C for Poly; ambient temperatures of 40°C; emissivity 0.9; 2ft/sec. wind in sun.

** To determine current ampacity by conductor size, please consult The National Electric Code, latest edition.

The data is approximate and subject to normal manufacturing tolerances.